Engine air intake tubes are crucial for vehicle performance, directing clean atmospheric air into engines for optimal combustion. This text examines materials used in these tubes, including steel and aluminium (known for durability but potential drawbacks in weight and vibration), plastic (lightweight, affordable, but may not withstand extreme conditions), and emerging composite materials. Selection requires balancing performance needs with compatibility, durability, and airflow efficiency to ensure seamless integration with exhaust systems and other components while enduring heat, pressure changes, corrosion, and wear.

Engine air intake tubes play a vital role in optimizing your vehicle’s performance. These tubes facilitate the flow of clean, cool air into your engine, enhancing power and efficiency. This article explores the key materials used in engine air intake tubes—from plastic and aluminum to stainless steel and carbon fiber—examining their pros and cons. We’ll guide you through essential factors to consider when choosing the best material for optimal engine performance and longevity.

- Understanding Engine Air Intake Tubes: Their Role and Function

- Key Materials Used in Engine Air Intake Tubes: Pros and Cons

- Factors to Consider When Choosing the Best Material for Engine Air Intake Tubes

Understanding Engine Air Intake Tubes: Their Role and Function

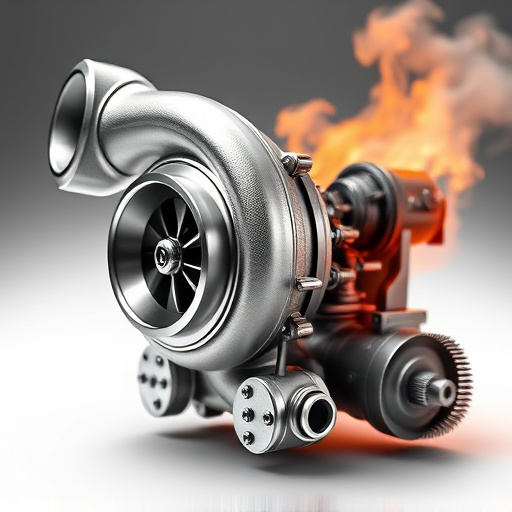

Engine air intake tubes are a critical component in any vehicle’s performance and efficiency. Their primary role is to facilitate the flow of atmospheric air into the engine, enabling optimal combustion and power generation. These tubes form part of the broader air intake systems, which also include filters, sensors, and other components that work together to ensure clean, adequate, and timely air supply to the internal combustion engine.

Effective engine air intake is crucial for enhancing vehicle performance. The right air intake system can improve throttle response, increase horsepower, and boost torque. This is especially important when paired with high-performance suspension kits, as it allows the vehicle to handle and perform better under various driving conditions. By understanding how air intake tubes function, automotive enthusiasts and mechanics can make informed decisions about materials and designs that best suit their vehicles’ needs.

Key Materials Used in Engine Air Intake Tubes: Pros and Cons

When it comes to engine air intake tubes, several materials compete for the top spot, each with its own unique advantages and drawbacks. The primary choice often falls on metal and plastic, but newer options like composite materials are gaining traction for their performance benefits.

Metal: Steel and aluminium are popular choices due to their durability and resistance to corrosion, making them ideal for harsh engine environments. Metal tubes offer excellent heat dissipation, which is crucial for maintaining optimal vehicle performance. However, they can be heavier, potentially affecting fuel efficiency, and more prone to vibrations, leading to noise issues. Additionally, installation might require muffler tips or coilover kits to achieve a perfect fit, adding complexity and cost.

Plastic: Lightweight and flexible, plastic air intake tubes are known for their simplicity and affordability. They offer excellent durability and resistance to high temperatures, making them suitable for many vehicles. Plastic components can be easily customised for specific vehicle models, providing a more precise fit. However, plastic may not withstand extreme conditions as well as metal and is more susceptible to cracking over time, impacting airflow and potentially affecting vehicle performance.

Factors to Consider When Choosing the Best Material for Engine Air Intake Tubes

When selecting materials for engine air intake tubes, several key factors come into play. Firstly, consider the vehicle performance requirements; different materials offer varying levels of airflow efficiency, which directly impacts the overall performance of your engine. For instance, high-flow plastic intakes can significantly boost power and torque in modified vehicles.

Secondly, think about compatibility with existing exhaust systems and brake components. Ensure that the chosen material aligns with your vehicle’s setup; certain materials may require specific connections or modifications to integrate seamlessly. Additionally, material selection should account for durability, resistance to heat and pressure changes, as well as protection against corrosion and wear over time.

Choosing the right material for your engine’s air intake tubes is crucial for optimal performance. While various options are available, high-quality materials like stainless steel and silicone offer superior durability, resistance to extreme temperatures, and minimal expansion or contraction. These properties ensure a consistent air flow, enhancing engine efficiency and power output. When selecting an air intake tube material, consider factors such as climate conditions, temperature extremes, and the specific requirements of your vehicle’s engine for a seamless and efficient performance upgrade.